HDD drilling – economic solution for building pipelines especially on soft soils

Horizontal directional drilling is ecological and efficient technology, which results in remarkable solutions.

Horizontal directional drilling has developed into a superior technology, and it should be favoured because of its ecology in many targets.

Horizontal directional drilling without spoiling the scenery

Horizontal directional drilling is a good solution in situations where infrastructure is built under ground or road without big trenches and without wrecking the scenery or disturbing the traffic. This way many solutions can be made by using ecological and modern technology.

Good planning in the beginning of the project provides the best qualifications

Horizontal directional drilling is already much more common than earlier. The reason why it is not yet more widely used are the rooted habits of infra designers to use old methods like using excavators to do the digging and opening trenches. Horizontal directional drilling is today more and more used in pulling pipes and cables. It is important in the future to consider horizontal directional drilling as an option in infra projects because it is a progressive method, environmentally and landscape friendly and quick method which is well suited for different soil types.

Horizontal directional drilling enables quick and efficient solutions

Horizontal directional drilling is efficient, environmentally friendly, quick and economical way to carry out work in different kinds of soils. In addition, directional drilling is a landscape friendly method and risks of damaging ground water are small.

Directional drilling can be used to drill up to 1500 meters. Most cost effective are drillings to 500 meter or less.

Horizontal directional drilling is a sensible alternative in targets, where digging is impossible or the traffic arrangements and/or finishing work cause big costs.

Horizontal directional drilling is a guidable drilling method, which enables underground infra installation without disturbing excavations and breaking of surfaces.

Method is well applicable in city sites, nature reserve areas and other sites, where digging is impossible or unwanted.

HDD guided directional drilling is well suited for drilling under rivers, roads, railways, runways and natural obstacles in the nature. The deeper the drilling and the softer the conditions, the better the competitiveness compared to other methods.

Applications

- Water and sewage pipes

- Oil and gas lines

- Gravity sewerlines

- Soft areas like mosses, water areas and nature reserve areas

- Subsurface drains to landfills and other similar places

- Drilling under roads etc.

Diameters and restrictions

- Length up to 1500 meters depends on pipe material and machinery, however maximum 500 meter installations are most economical to perform

- Diameters from 50mm to 1200mm

- Suitable soil: clay, silt and sand

- Problematic soil: moraine and rock

Suitable for

- Rivers

- Roads and railways

- Runways

- Long distances

- Natural obstacles

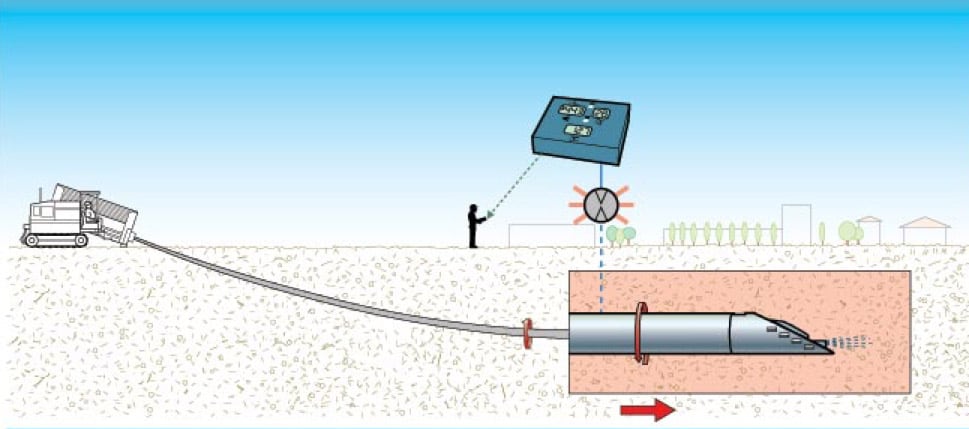

Stage 1

Guiding is carried out by using a measuring sensor located just behind the drilling head. The sensor communicates with the control unit of the drilling machine.

HDD – drilling is a technique where a small diameter pilot hole is drilled along a beforehand planned line to the pipeside. In soft soils the pilot hole is drilled by using high pressure flushing and similarly in hard soil by using a so-called mud motor.

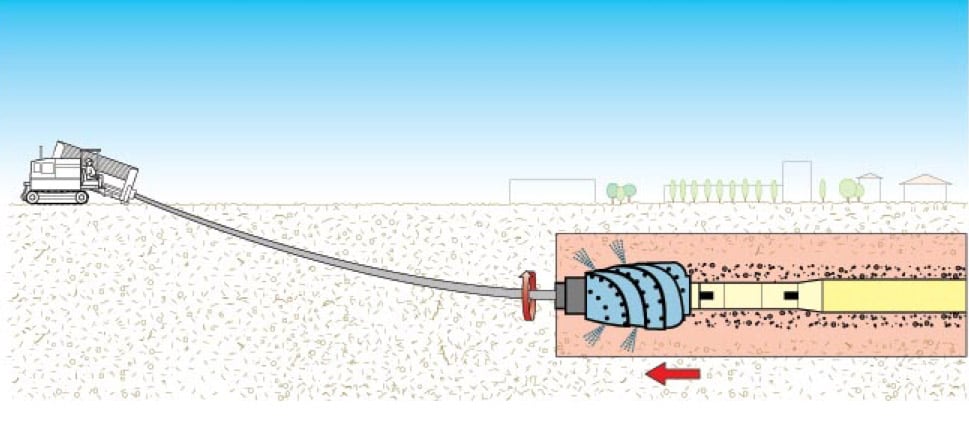

Stage 2

When the target pit has been reached, the measuring sensor and drill head are removed and they are replaced by an reaming tool and rotatable connection, which is connected to the product pipe. When pulling the pipe, the bentonite solution lubricates and protects its outer diameter in a way that in time the pipe will adapt to the clay maddrass.